Nature is both breathtakingly beautiful and unforgivingly harsh. For those who venture...

The Mind-Blowing Engineering Behind Boeing’s Powerhouse

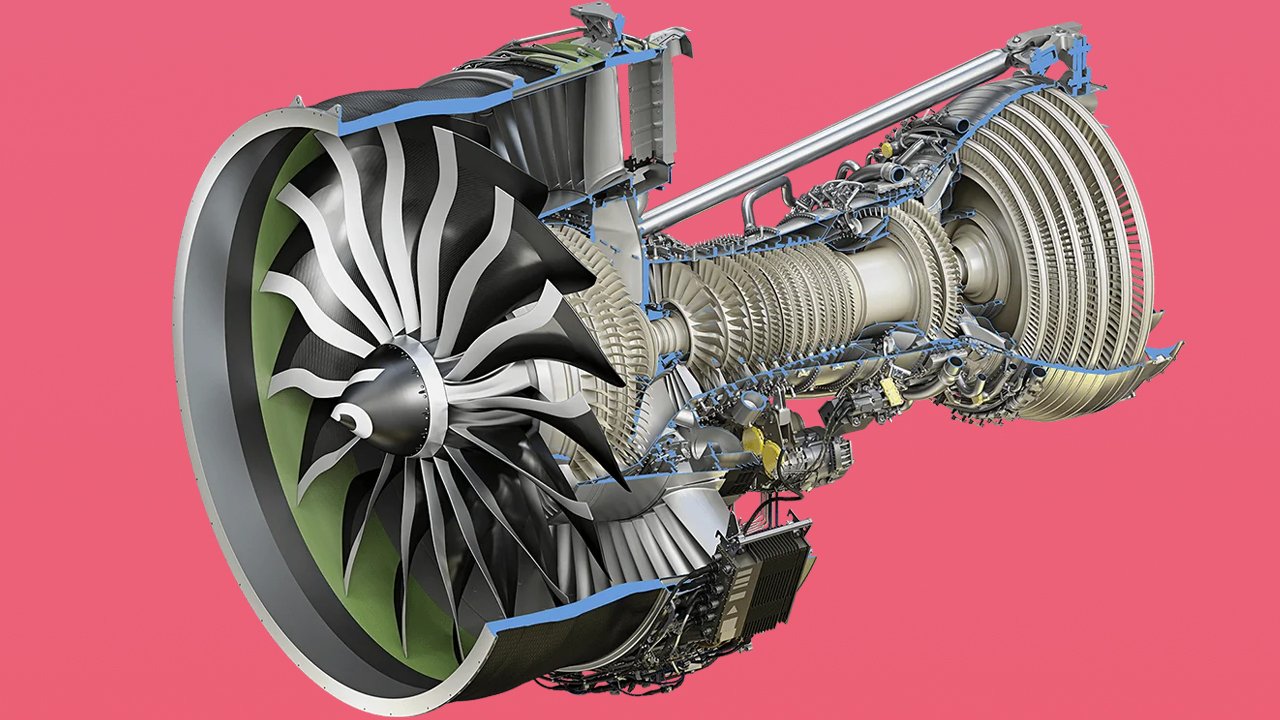

The aviation industry has seen remarkable advancements in engine technology over the decades, and one of the most impressive feats of modern engineering is the General Electric GEnX engine. Designed for the Boeing 787 Dreamliner and the 747-8, the GEnX engine is a masterpiece of aerodynamics, fuel efficiency, and cutting-edge materials science. With its revolutionary design, this high-bypass turbofan engine pushes the boundaries of aviation technology, setting new standards for performance and sustainability.

Lightweight and Durable Design

One of the most striking aspects of the GEnX engine is its use of advanced composite materials. Unlike traditional jet engines that rely on heavier metal components, the GEnX features composite fan blades and fan case, reducing the overall weight while maintaining structural integrity. This not only improves fuel efficiency but also enhances durability, ensuring the engine has a longer operational lifespan.

Fuel Efficiency and Reduced Emissions

The GEnX is designed with fuel efficiency as a priority. Compared to older engines, it offers up to 15% better fuel efficiency, significantly lowering operational costs for airlines. This is achieved through several innovations, including a lean-burn combustion system that optimizes fuel usage while reducing nitrogen oxide emissions. The engine’s bypass ratio is also higher, meaning more air is directed around the core, leading to better thrust with lower fuel consumption.

Advanced Cooling and Noise Reduction

Jet engines generate immense heat, and managing it effectively is crucial for performance and longevity. The GEnX incorporates an advanced cooling system that uses ceramic matrix composites (CMCs) in the turbine section. These CMCs can withstand extreme temperatures, reducing the need for additional cooling and improving overall efficiency.

Noise pollution is a major concern in aviation, and the GEnX addresses this with innovative acoustic technology. The fan blades are designed to minimize noise, and the engine features chevron nozzles on the exhaust, which help reduce turbulence and lower decibel levels during takeoff and landing. This makes the GEnX one of the quietest jet engines in its class.

Cutting-Edge Manufacturing Techniques

The GEnX engine benefits from state-of-the-art manufacturing processes, including 3D printing. Some of its components are additively manufactured, allowing for greater design flexibility and weight reduction. This not only improves efficiency but also speeds up production times while maintaining precision engineering standards.

Sustainability and the Future of Aviation

As the aviation industry moves toward sustainability, the GEnX engine plays a pivotal role in reducing carbon footprints. Its fuel-efficient design significantly cuts CO2 emissions, making air travel more environmentally friendly. Furthermore, ongoing advancements in biofuels and hybrid-electric propulsion technologies could further enhance the engine’s sustainability in the years to come.

The GEnX engine is a testament to the incredible strides made in aviation engineering. From its composite materials and fuel-efficient operation to its advanced cooling systems and noise reduction technology, every aspect of its design is a marvel of innovation. As the demand for cleaner and more efficient air travel grows, the GEnX stands at the forefront of the industry, redefining what’s possible in modern aviation.

Hot

Recent

Don't miss those

When it comes to flawless beauty and radiant skin, Hailey Bieber is...

The United States Air Force has achieved a significant milestone with the...

In a world where challenges often seem overwhelming, glimpses of real-life heroes...

The humble potato, a staple food for millions across the globe, holds...

The humble potato, a staple food for millions across the globe, holds...